Our Expertise

MANUFACTURING CAPABILITIES

Dan-Loc has the expertise, tooling, machinery and processes you require to manufacture the products you need.

MATERIAL OPTIONS

Dan-Loc is experienced in all ASTM A193, A194 and A320 Grades and exotics like Gracde 660, Monel, Inconel, Hastelloy in FERITTIC and AUSTENITIC STEELS.

QUALITY AND CERTIFICATIONS

Peace of mind with our ISO 9001 Registered Quality Assurance, our proven quality standards and industry certifications.

Manufacturing Capabilities

Below are some of the manufacturing capabilities of Dan-Loc:

- Cutting – High-speed band saws cut threaded bar to discrete bolt lengths.

- Threading – roll form threading, cut threading, and oversize tapping of nuts for coatings.

- Blast Cleaning – coiled steel bar is blast cleaned before drawing.

- CNC machining – lathes, mills.

- Materials Analysis – all incoming raw material is positively identified using X-ray fluorescence technology.

- Metals Physical Properties Analysis – Dan-Loc’s onsite laboratory performs tensile, charpy, and proof load testing of products.

- Hardness Testing – Rockwell, Brinell, and eddy current hardness evaluations.

- Heat Treating/Modifying – Dan-Loc operates three furnaces for a capacity of 3,000 lbs./hr.

- Coating/Plating – zinc, cadmium, moly disufide, chrome, silver, gold, Xylan®, Xylar®, Teflon®, and other specialty plating/coating.

Dan-Loc Special Products

“Specials” are defined as manufactured bolts or other products whose final configurations are non-traditional with respect to industry association standards featured by ASTM, SAE, or ASME. They may consist of atypical diameters, lengths, or other attributes such as hex flats, milled surfaces, grooves, contours, special threads, or any number of geometric variations from traditional products that involve custom engineering.

They also may require fabrication from exotic materials, include unique coatings, are subjected to specialized treatments such as shot peening, require rigorous engineering focus, or exhibit a variety of characteristics that do not fall neatly within the definition of standard products. Dan-Loc Group is capable of manufacturing these special products in addition to its standard product offerings

MATERIAL OPTIONS

Dan-Loc provides threaded products in a wide variety of materials from alloy and stainless steel to exotics. These materials include ASTM A193 and ASTM A320 grades for threaded studs and ASTM A194 grades for nuts.

FERRITIC STEEL

ASTM A193 Grades

- B7

- B7M

- B6 (410 SS)

- B16

ASTM A320 Grades

- L7

- L7M

- L43

AUSTENITIC STEEL

ASTM A193 Grades

- B8, (304 SS) Class 1 & 2

- B8M, (316 SS) Class 1& 2

ASTM A320 Grades

- B8A, (304 SS) Class 1 & 2

- B8MA, (316 SS) Class 1 & 2

Exotics

- Grade 660

- Monel®

- Inconel®

- Hastelloy®

ASTM A194 Nut Grades

- 2H

- 2HM

- Grade 3

- Grade 7

- Grade 8

- Grade 8M

- Grade 8A

- Grade 8MA

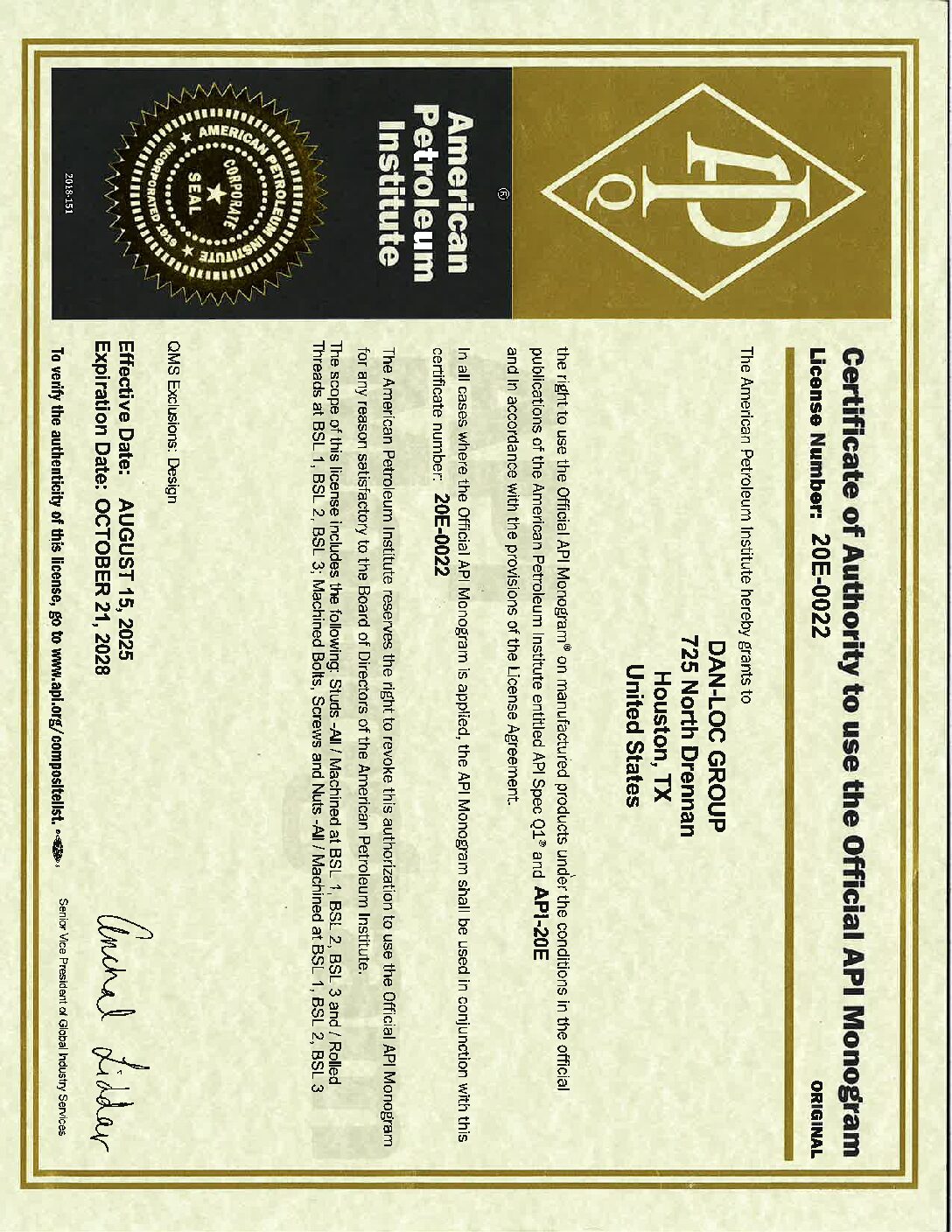

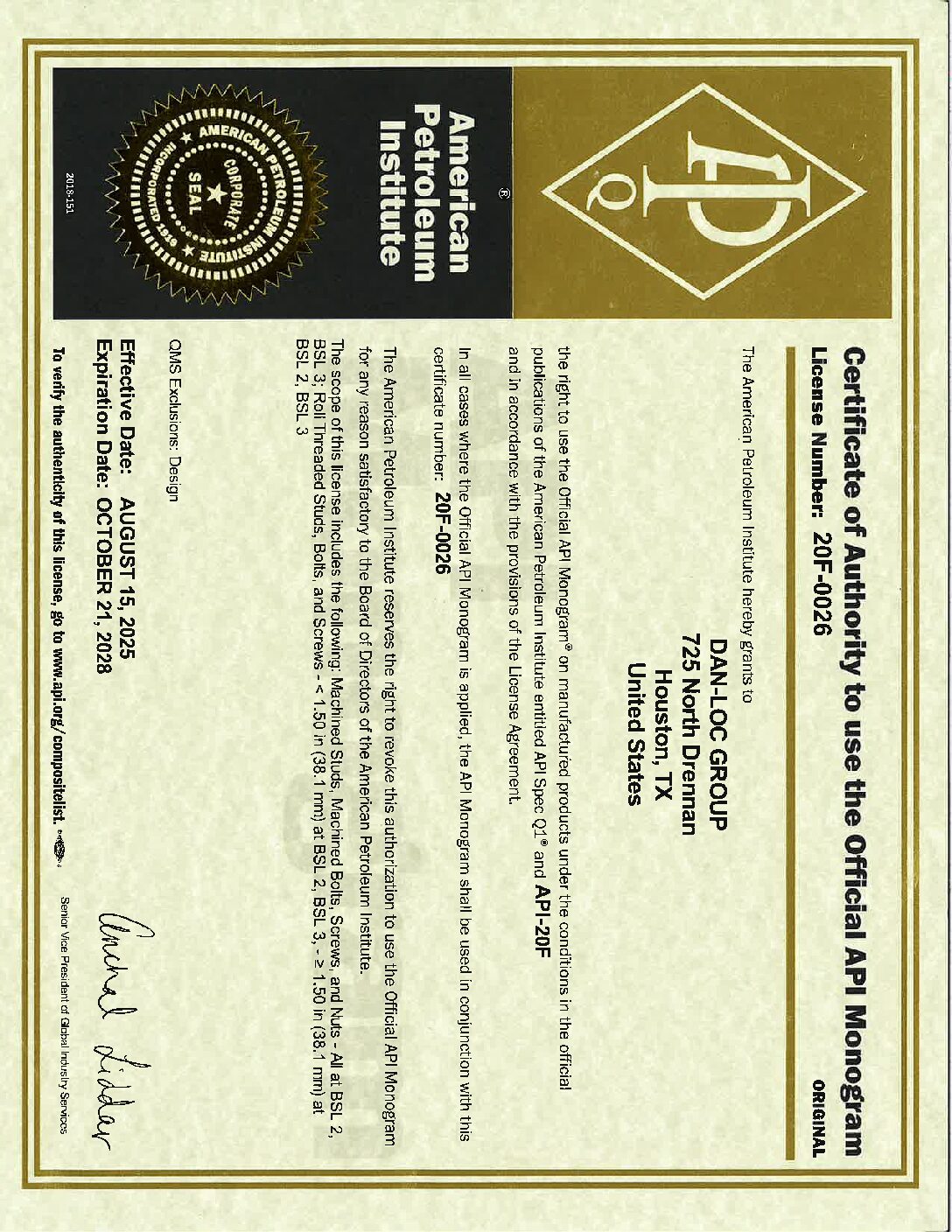

Quality Standards

![]()

![]()

![]()

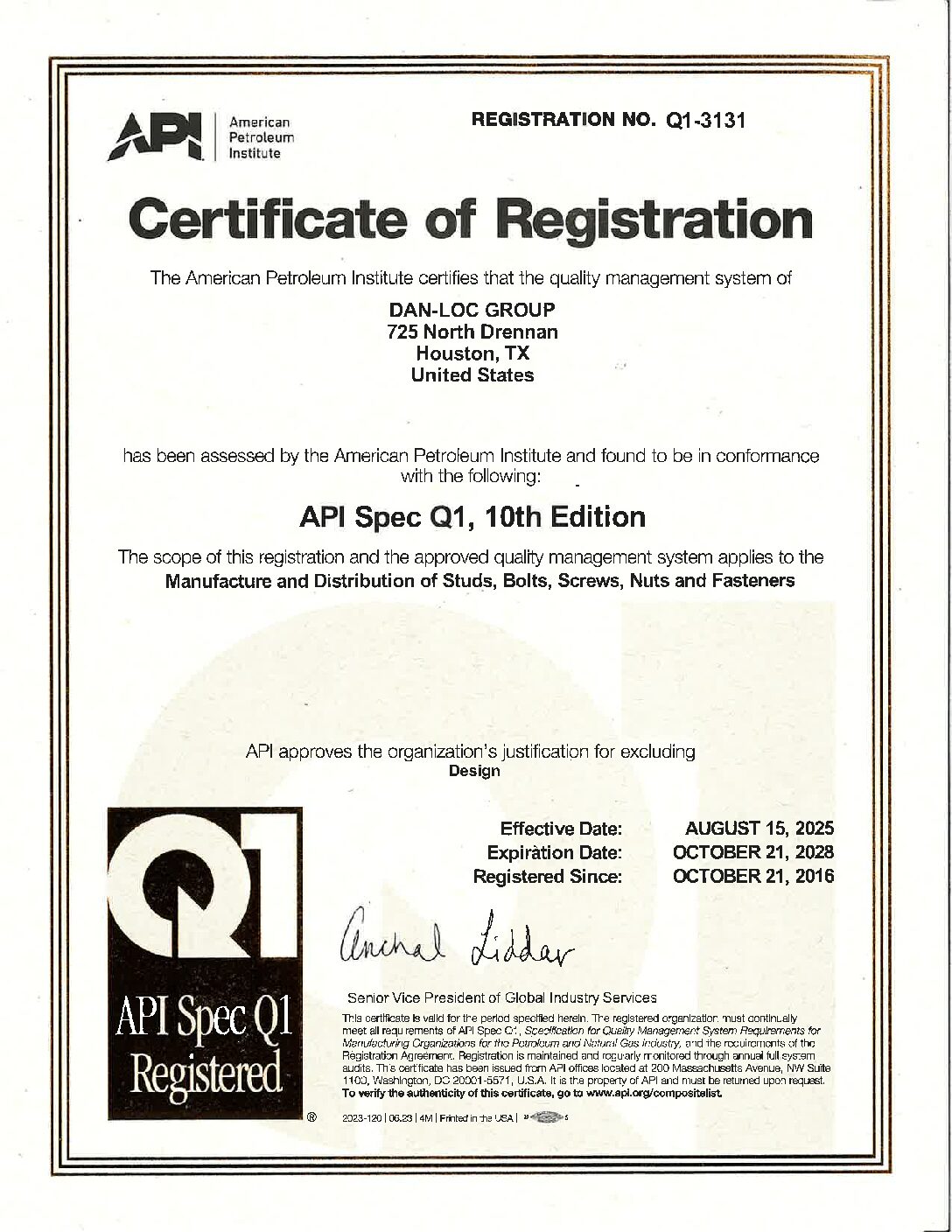

Dan-Loc Group has established a strict guideline of quality assurance and is ISO 9001 Registered. Our quality assurance manual is available upon request. We are also in compliance with the National Fastener Act.

Your operation can’t risk failures. You have to know that you’re getting quality products that live up to your performance requirements. Dan-Loc Group goes above and beyond to give you this level of assurance.

Dan-Loc Group has been granted approval from the American Petroleum Institute to use the API Spec 20E Monogram (license number 20E-0022), in addition to API Spec Q1 Manufacturing Certification. These API certifications along with ISO 9001:2015 Registration show Dan-Loc Group’s continued commitment to providing the highest quality bolting and sealing products to an international customer base in the global petroleum and natural gas industry.

There are several stages that go into the manufacturing process, and Dan-Loc Group leaves nothing to chance with any of them, including the sourcing of our raw materials. All of our steel comes from mills that we know and have worked with for a long time. These mills perform vacuum degassing and controlled diameter reduction to ensure quality and make the steel cleaner and stronger. Yet, even though we have immense confidence in our suppliers, we still test our incoming material, so you can have immense confidence in our products. We perform Positive Material Identification (PMI) testing to ensure we have received what was expected and that it is manufactured to specification.

From PMI testing on, we handle every step ourselves in our Houston manufacturing facility. We use rigorous process controls in our heat-treating and roll-threading methods to attain the highest level of product reliability. Then we double check our work through exhaustive laboratory analysis. We mechanically test samples from each bolt production run to validate tensile and yield strength, elongation and reduction-of-area percentages, proper Charpy impact values for low temperature applications, and thread geometric integrity.

Our ultimate goal always is to provide the highest level of quality in everything we make and everything we do. We work to exceed industry standards in our products and to exceed customer expectations in our service. While stud bolts and ring joint gaskets may seem like simple items, they are critical components to our customers operations, and they absolutely must perform. We believe one of our greatest duties is to help our customers prevent failures, thus all of our procedures are geared toward reducing their risk, and boosting their confidence.

Why You Want Dan-Loc On Your Team

Dan-Loc is your trusted stud, rod, bolt, nut, fastener and gasket supply partner. We stock for your day-to-day needs, and are able to scale to projects of any size or manufacturing equipment customer need.

Let's Connect!

What can Dan-Loc do for you?

A knowledgeable representative will respond as soon as possible. Thank you!

Dan-Loc Locations

Dan-Loc wants you to have the information you need and answer any questions you have. Please fill out the contact form, email us, or give us a call on the number below.

HEADQUARTERS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - TEXAS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - LOUISIANA

6059 Commerce Pointe Drive, Geismar, LA 70734

Click to call: (225) 644-6449

DAN-LOC EXPRESS - OHIO

294 Fox Drive, Piqua, OH 45356

Click to call: (937) 778-0485

Terms & Conditions of Sale | Legal | Privacy Policy | Employee Portal |

© Copyright 1961-2021 Dan-Loc Group, Inc. All rights reserved. All logos are property of their respective owners.

![]()