Industrial fastener TECHNICAL INFORMATION

PRODUCT BROCHURES

A comprehensive and combined source for all product and company brochures.

Browse our library and get the information you need.

PRODUCT DATA

Browse the details of our product’s capabilities, material grades, coatings and general bolting and gasket information.

CONVERSION CHARTS

A full range of conversion charts for decimal equivalents, torque values, flange bolting and box quantities.

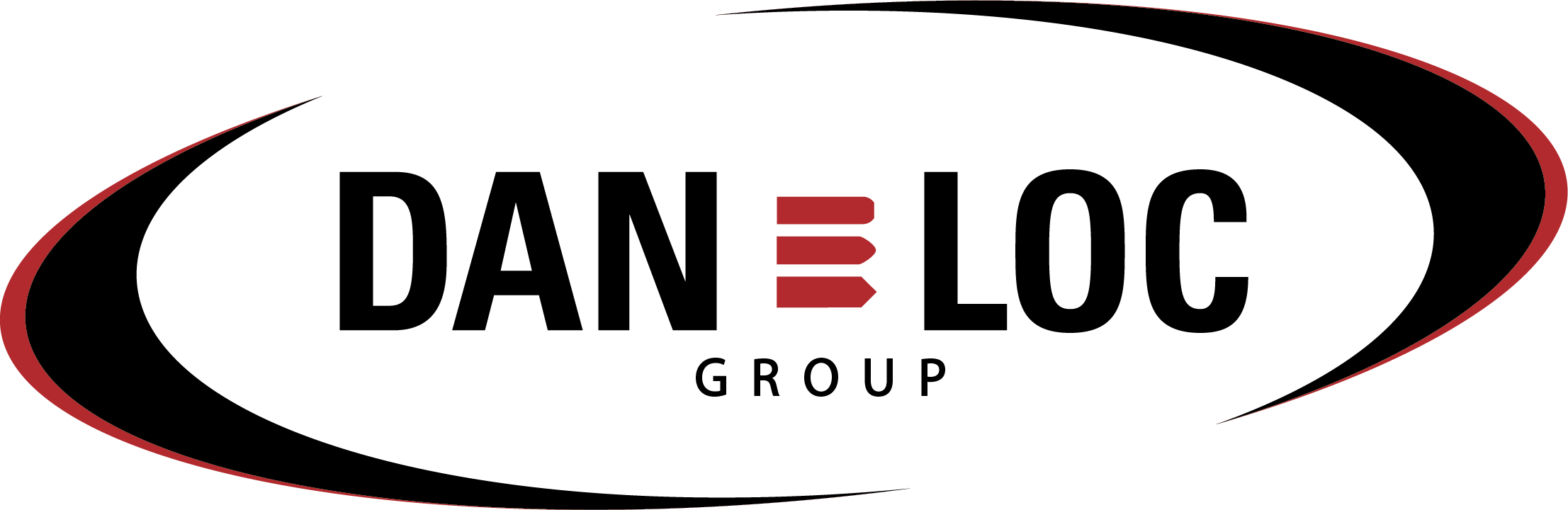

DAN-LOC THREADED PRODUCTS

DAN-LOC GASKET & SEAL PRODUCTS

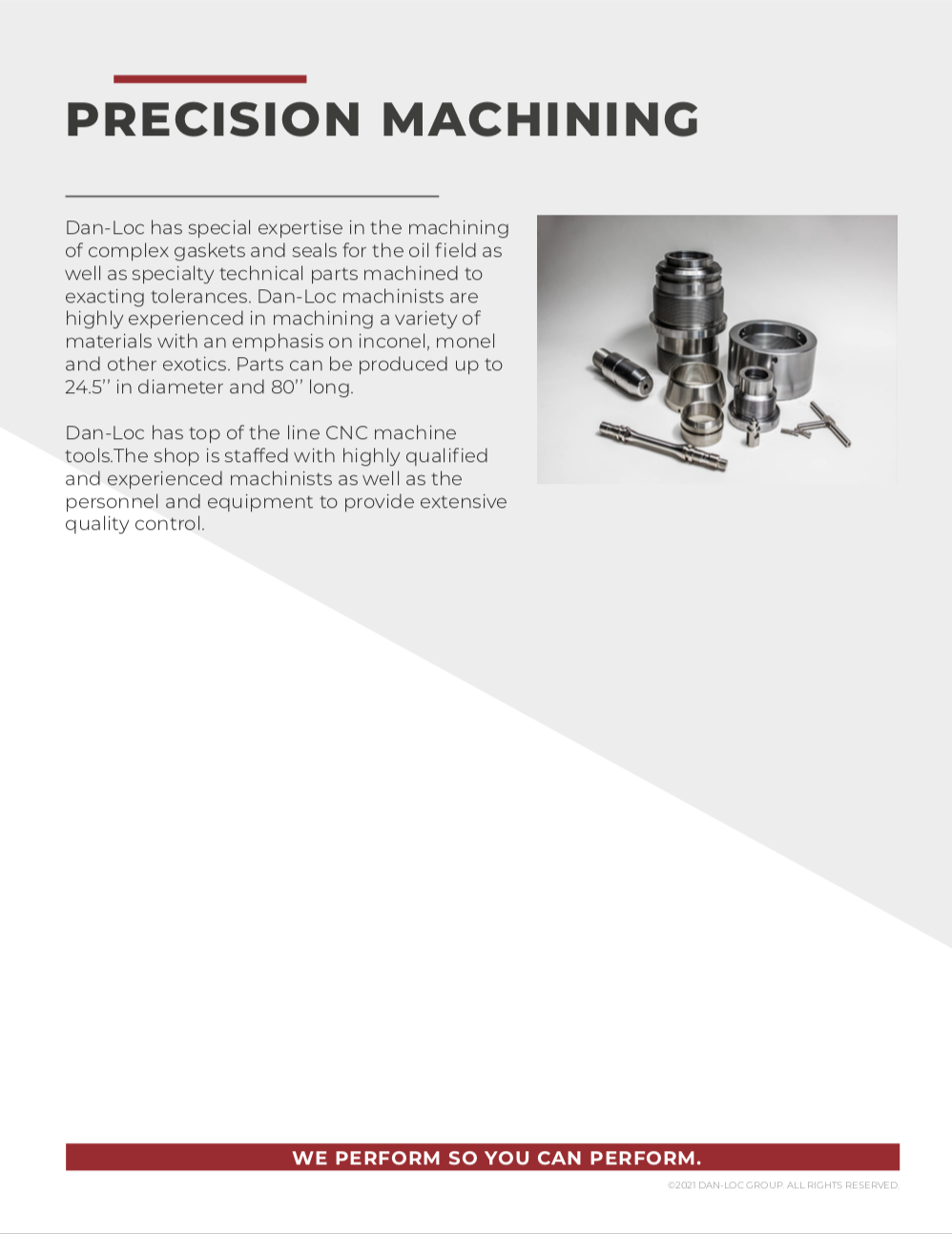

DAN-LOC PRECISION MACHINING

DAN-LOC TECHNICAL INFORMATION

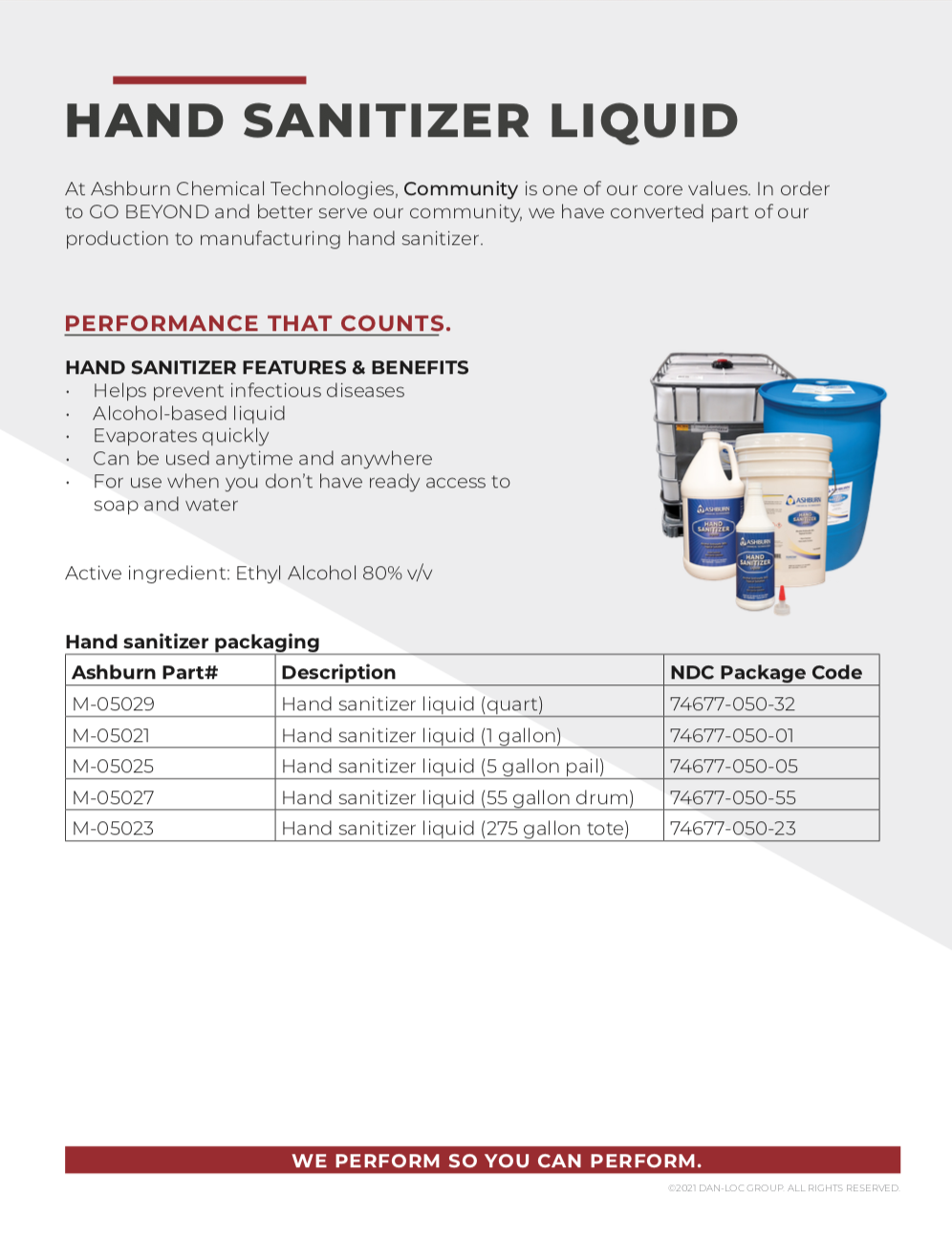

DAN-LOC SANITIZER & PPE

PRODUCT DATA

This information presents the Dan-Loc product capabilities for material grades, coatings, general bolting and gasket information.

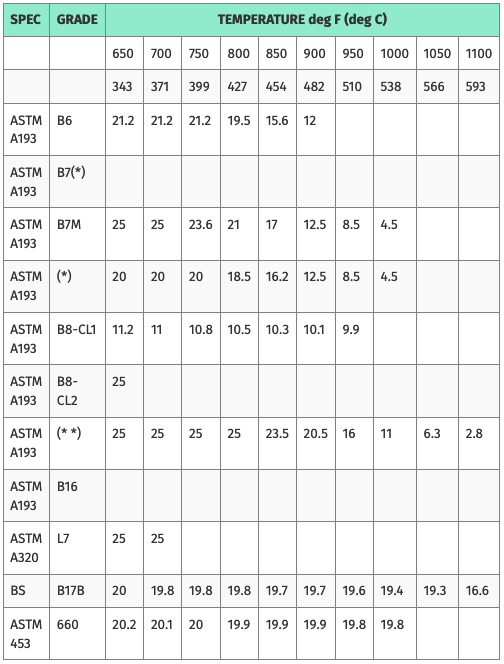

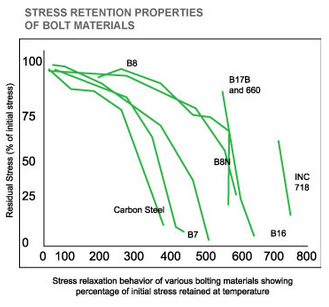

DESIGN STRESS VALUES (KSI) VS. TEMPERATURE

*for bolt diamters less than 2-1/2″

**for bolt diameters less than 3/4″

Please note that the above values are for reference purposes only. Values should be extracted from ASME or BS 5500.

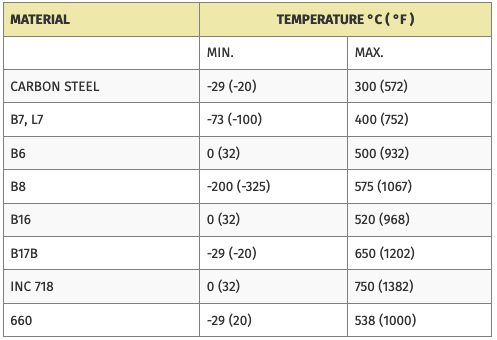

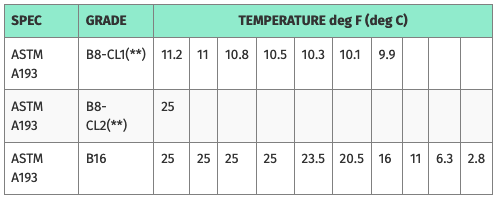

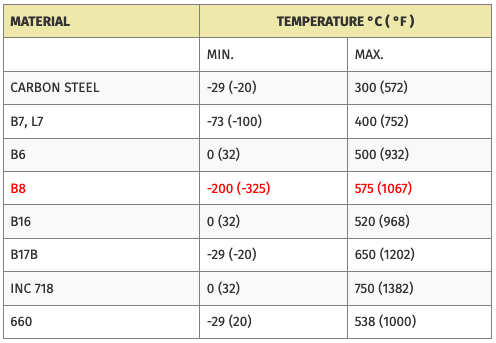

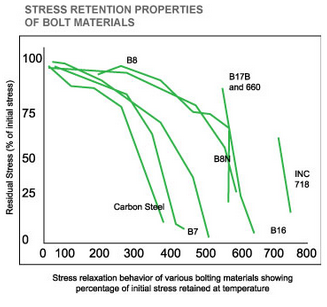

RECOMMENDED WORKING TEMPERATURES OF BOLT MATERIALS

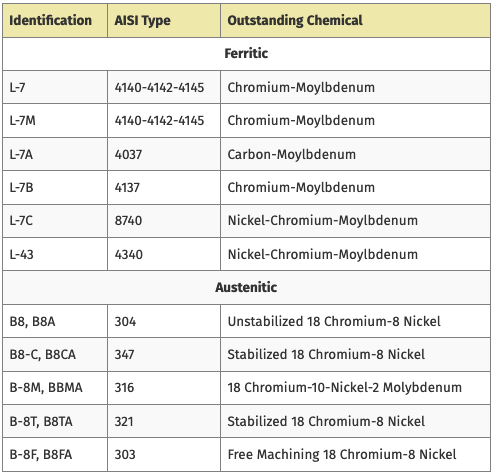

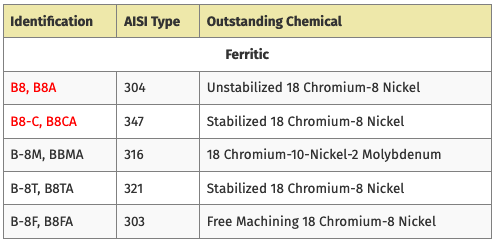

ASTM A – 194 “Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure and High-Temperature Service”

The Ferritic Steel Grades L7 and L7M together with the Austenitic Grades B8 and B8M are normally stocked for immediate shipment, with the other Grades available on special order. Grade L7 is normally used to -50°F without a Charpy Test and to -150°F with a Charpy Test. Grade L7M is normally used in H2S service with a required Charpy Test at -100°F. All of the Austenitic steels listed above may be used to -325°F without a Charpy Impact Test and at lower temperatures with the requisite Impact Tests.

ASTM A – 320 “Standard Specification for Alloy-Steel and Stainless-Steel Bolting Materials for Low-Temperature Service”

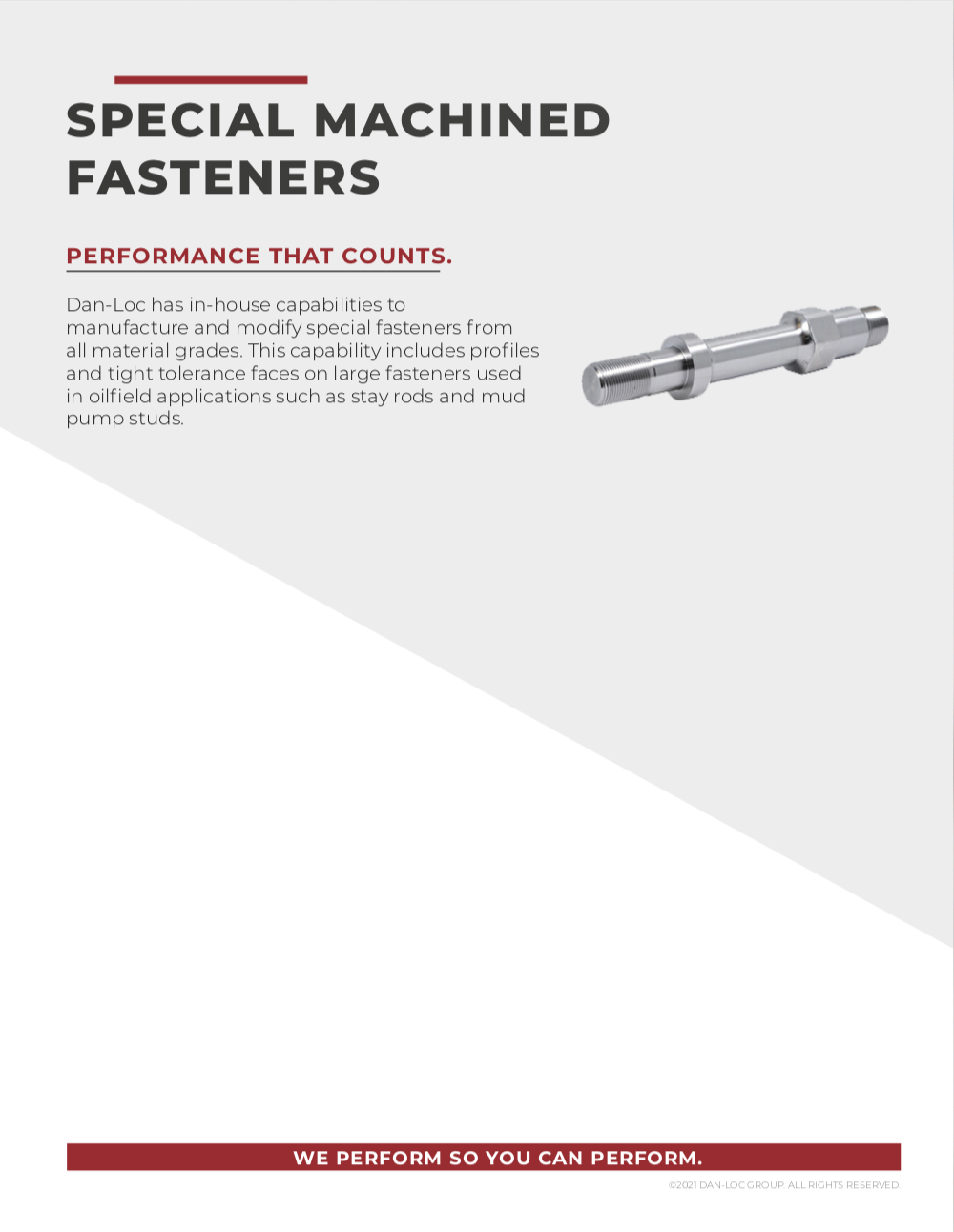

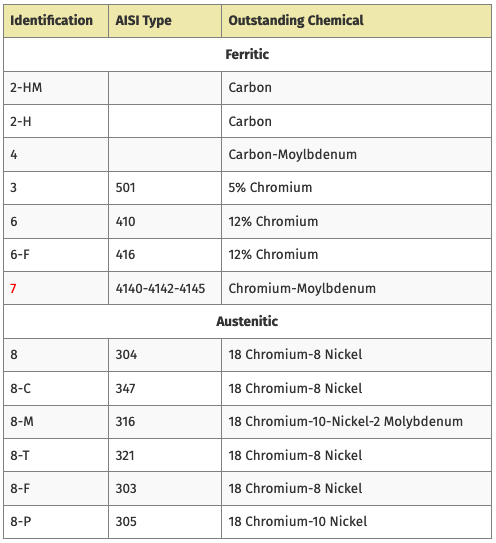

Dan-Loc stocks the Ferritic steel nuts in Grades 2H, 2HM, 7, L7, and L7M which are normally used in conjunction with Grade B7, B7M, B16, L7 and L7M studs. The Austenitic steel nuts, Grade 8 and 8M are also available from stock for use on stainless steel studs and bolts.

Dan-Loc stocks heavy pattern hex nuts in the grades listed above to the dimensional requirements of ANSI B18.22.1. Unless otherwise specified, these nuts are tapped UNC-2B in sizes 1” and under, and 8UN-2B over 1” diameter. All other grades of nuts listed may require special order.

DESIGN STRESS VALUES (KSI) VS. TEMPERATURE

Please note that the above values are for reference purposes only. Values should be extracted from ASME or BS 5500.

**For Bolt Diameters less than 3/4″

RECOMMENDED WORKING TEMPERATURES OF BOLT MATERIALS

ALL DAN-LOC STUD BOLTS ARE QUENCHED AND TEMPERED

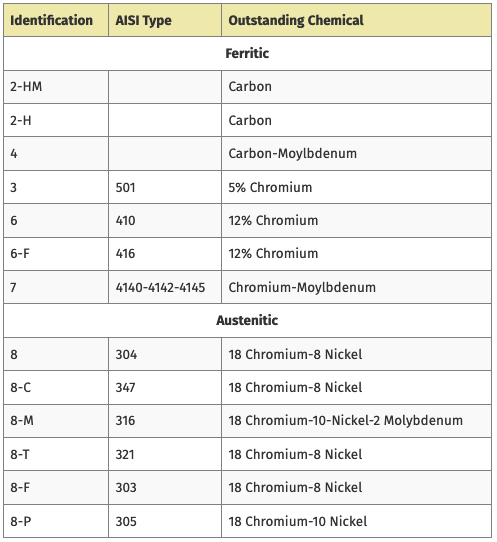

ASTM A – 194 “Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure and High-Temperature Service”

ASTM A – 320 “Standard Specification for Alloy-Steel and Stainless-Steel Bolting Materials for Low-Temperature Service”

FERRITIC STEEL

ASTM A193 Grades

- B7

- B7M

- B6 (410 SS)

- B16

ASTM A320 Grades

- L7

- L7M

- L43

AUSTENITIC STEEL

ASTM A193 Grades

- B8, (304 SS) Class 1 & 2

- B8M, (316 SS) Class 1& 2

ASTM A320 Grades

- B8A, (304 SS) Class 1 & 2

- B8MA, (316 SS) Class 1 & 2

Exotics

- Grade 660

- Monel®

- Inconel®

- Hastelloy®

ASTM A194 Nut Grades

- 2H

- 2HM

- Grade 3

- Grade 7

- Grade 8

- Grade 8M

- Grade 8A

- Grade 8MA

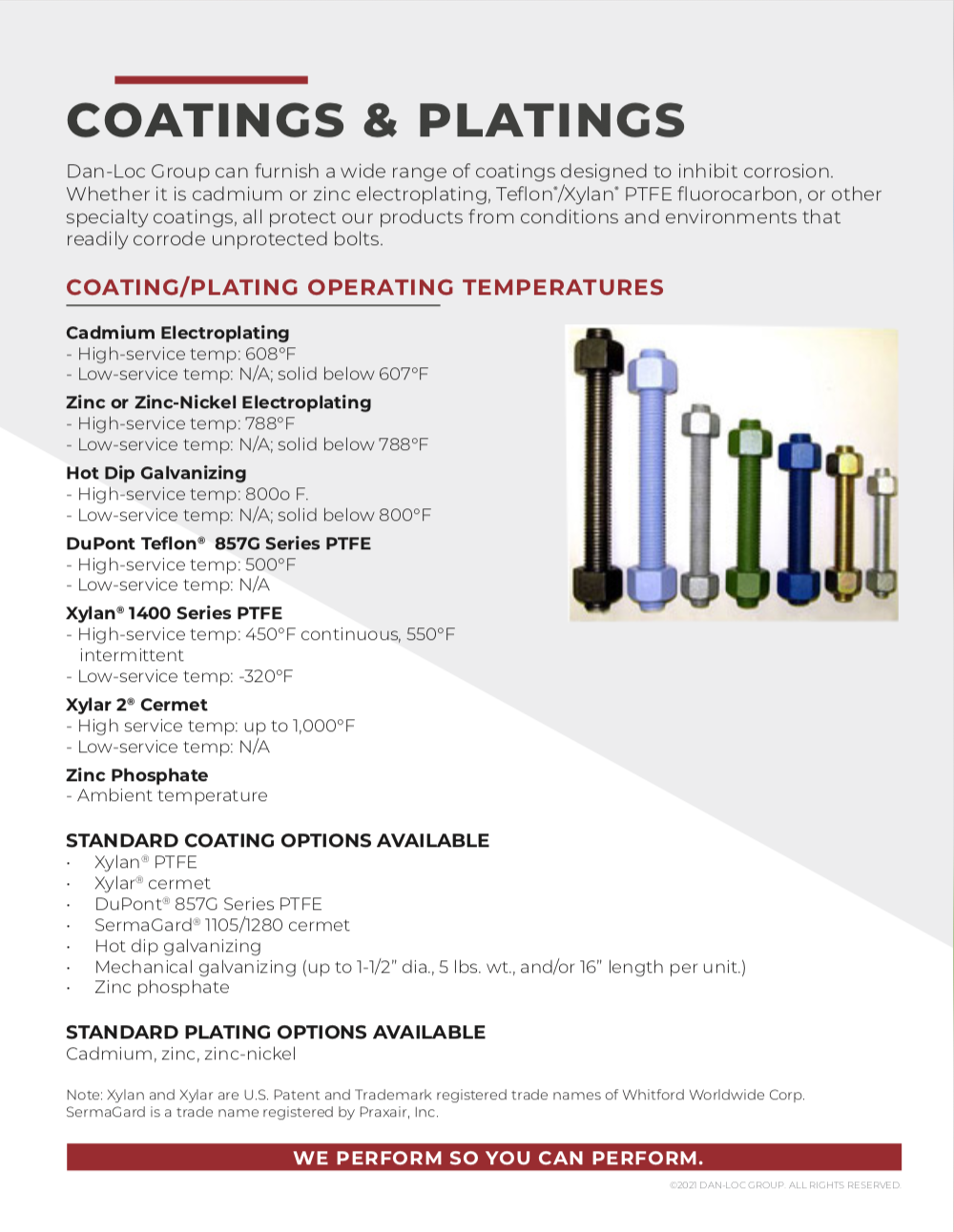

Dan-Loc Group can furnish a wide range of coatings designed to inhibit corrosion. Whether it is cadmium or zinc electroplating, Teflon/Xylan PTFE fluorocarbon, or other specialty coatings, all protect our products from conditions and environments that readily corrode unprotected bolts.

COATING/PLATING OPERATING TEMPERATURES

- Cadmium Electroplating

– High Service Temp: 608o F.

– Low Service Temp: N/A; solid below 607o F. - Zinc or Zinc-Nickel Electroplating

– High Service Temp: 788o F.

– Low Service Temp: N/A; solid below 788o F. - Hot Dip Galvanizing

– High Service Temp 800o F.

– Low Service Temp: N/A; solid below 800o - DuPont Teflon® 857G Series PTFE

– High Service Temp: 500o F.

– Low Service Temp: N/A - Xylan® 1400 Series PTFE

– High Service Temp: 450o F. continuous, 550o F. intermittent

– Low Service Temp: -320o F. - Xylar 2® Cermet

– High Service Temp: up to 1,000o F.

– Low Service Temp: N/A - Zinc Phosphate

– Ambient Temperature

STANDARD COATING OPTIONS AVAILABLE

- Xylan® PTFE

- Xylar® Cermet

- DuPont® 857G Series PTFE

- SermaGard® 1105/1280 Cermet

- Hot Dip Galvanizing

- Mechanical Galvanizing (up to 1-1/2” dia., 5 lbs. wt., and/or 16” length per unit.)

- Zinc Phosphate

STANDARD PLATING OPTIONS AVAILABLE

- Cadmium

- Zinc

- Zinc-Nickel

Note: Xylan and Xylar are U.S. Patent & Trademark registered trade names of Whitford Worldwide Corp.

SermaGard is a trade name registered by Praxair, Inc.

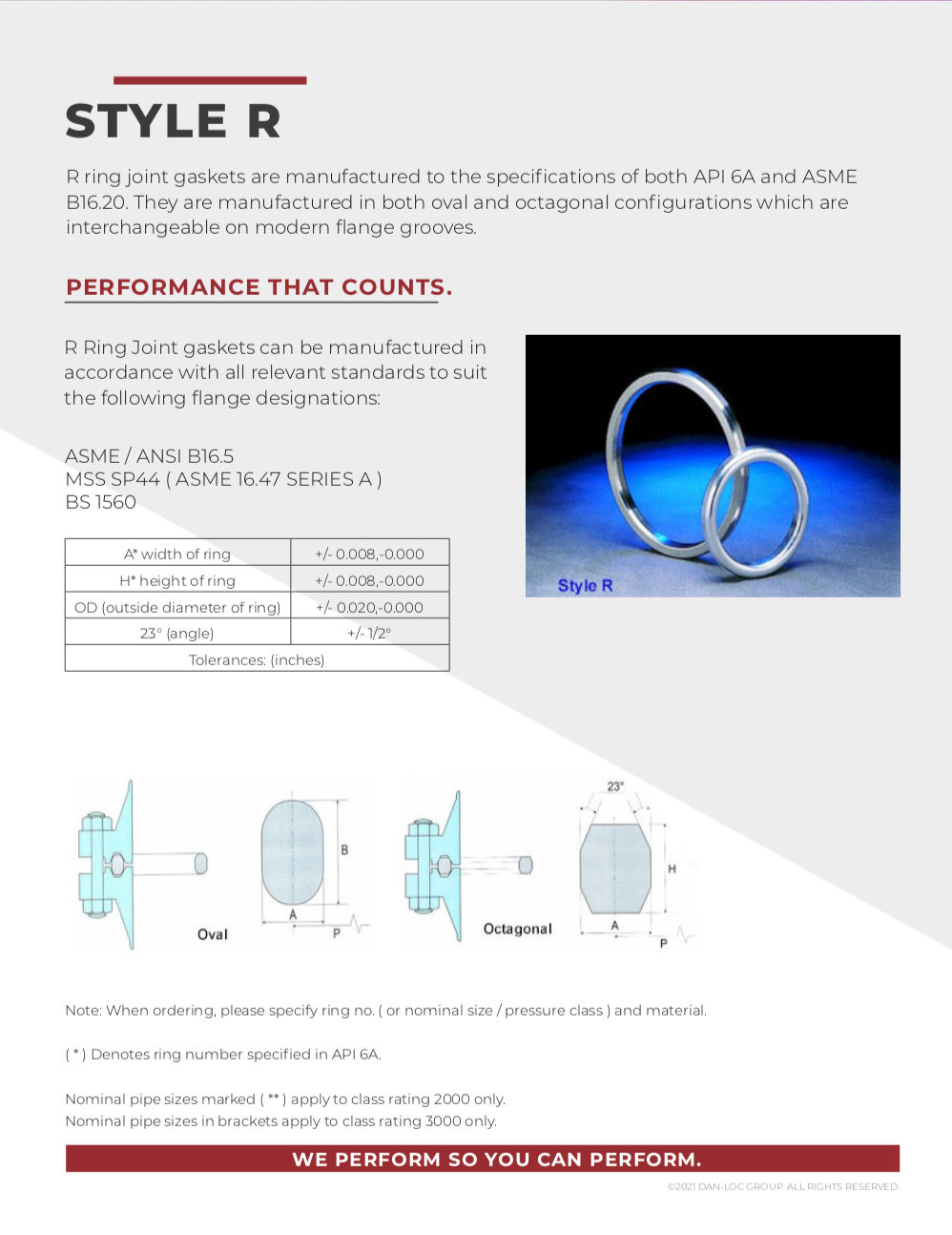

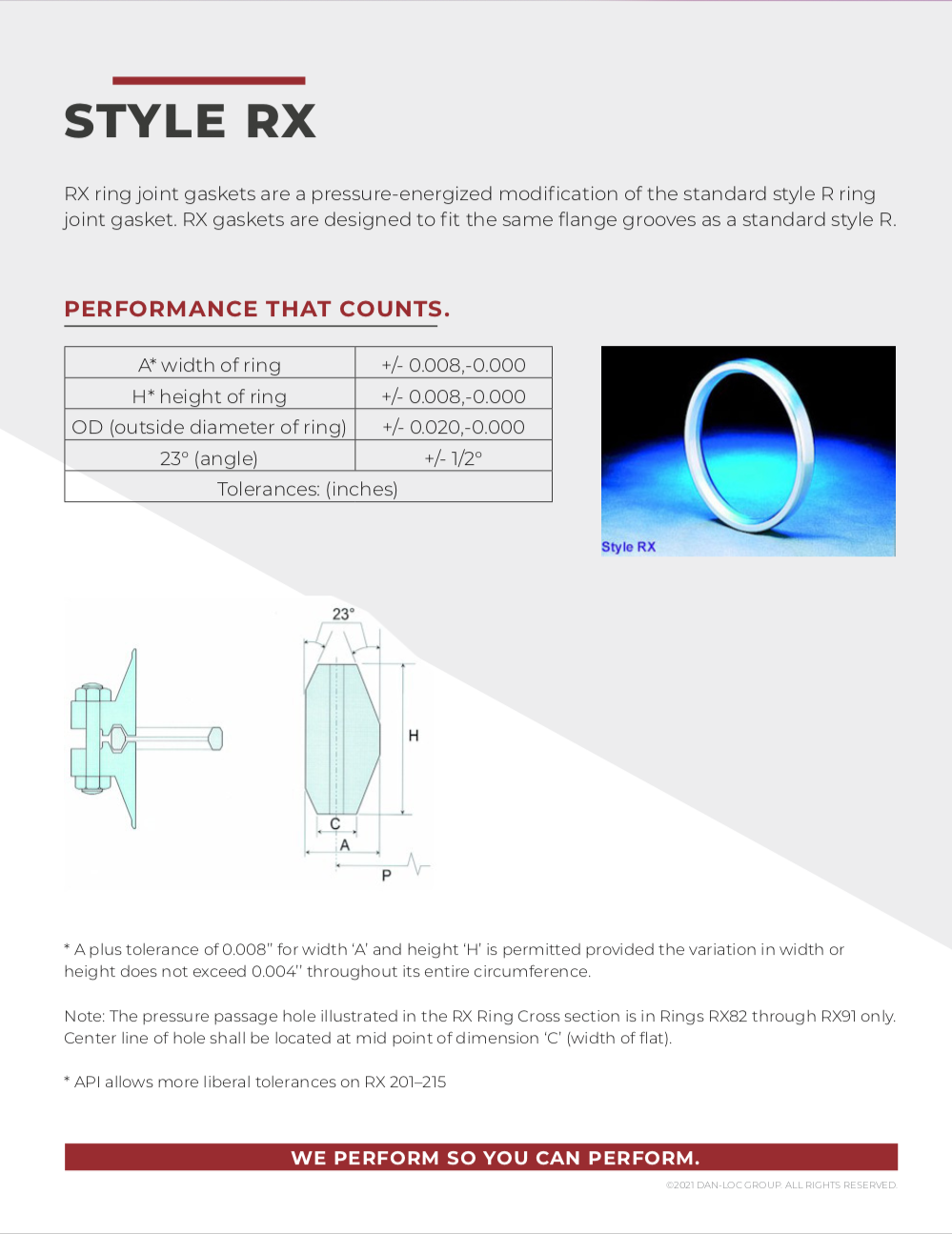

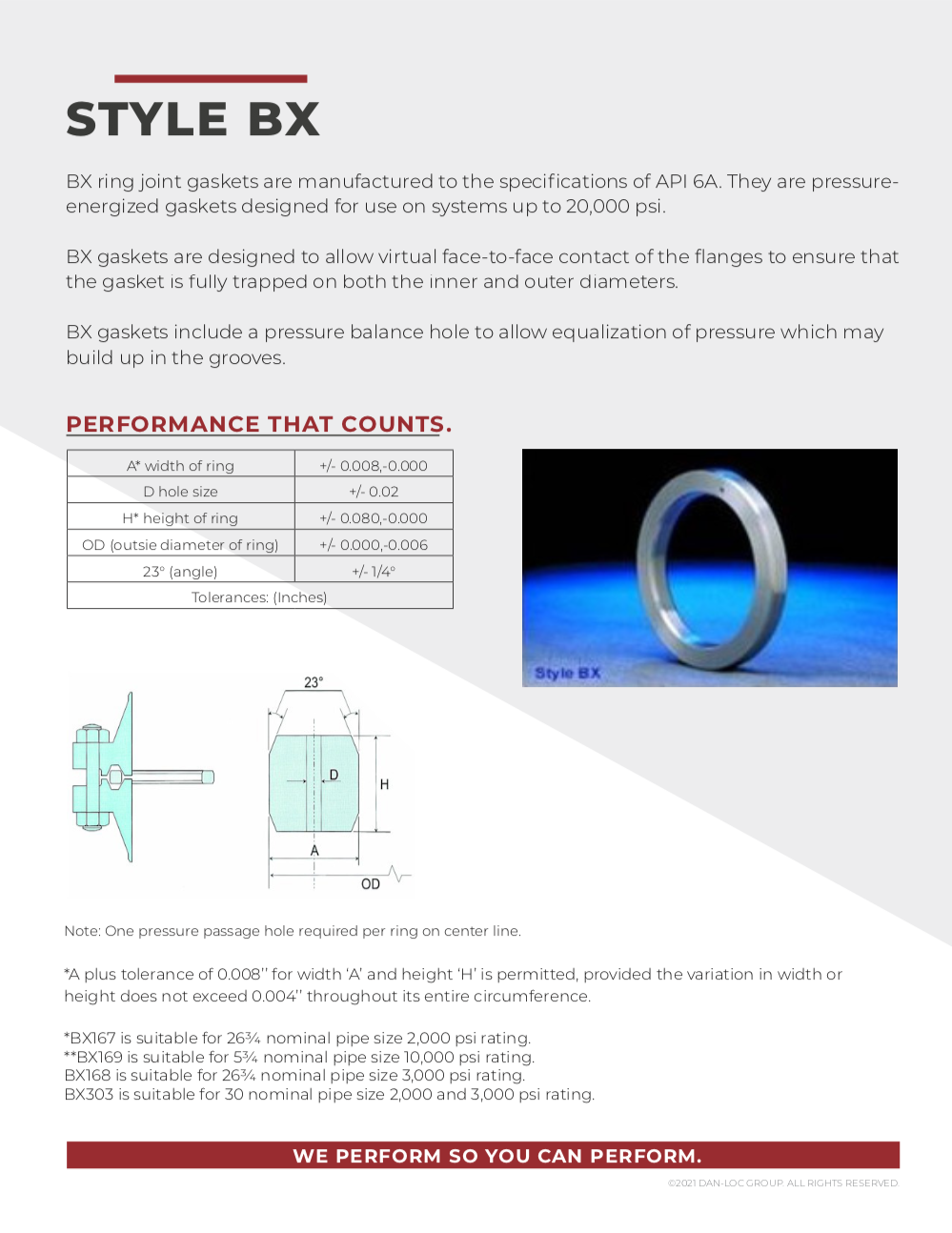

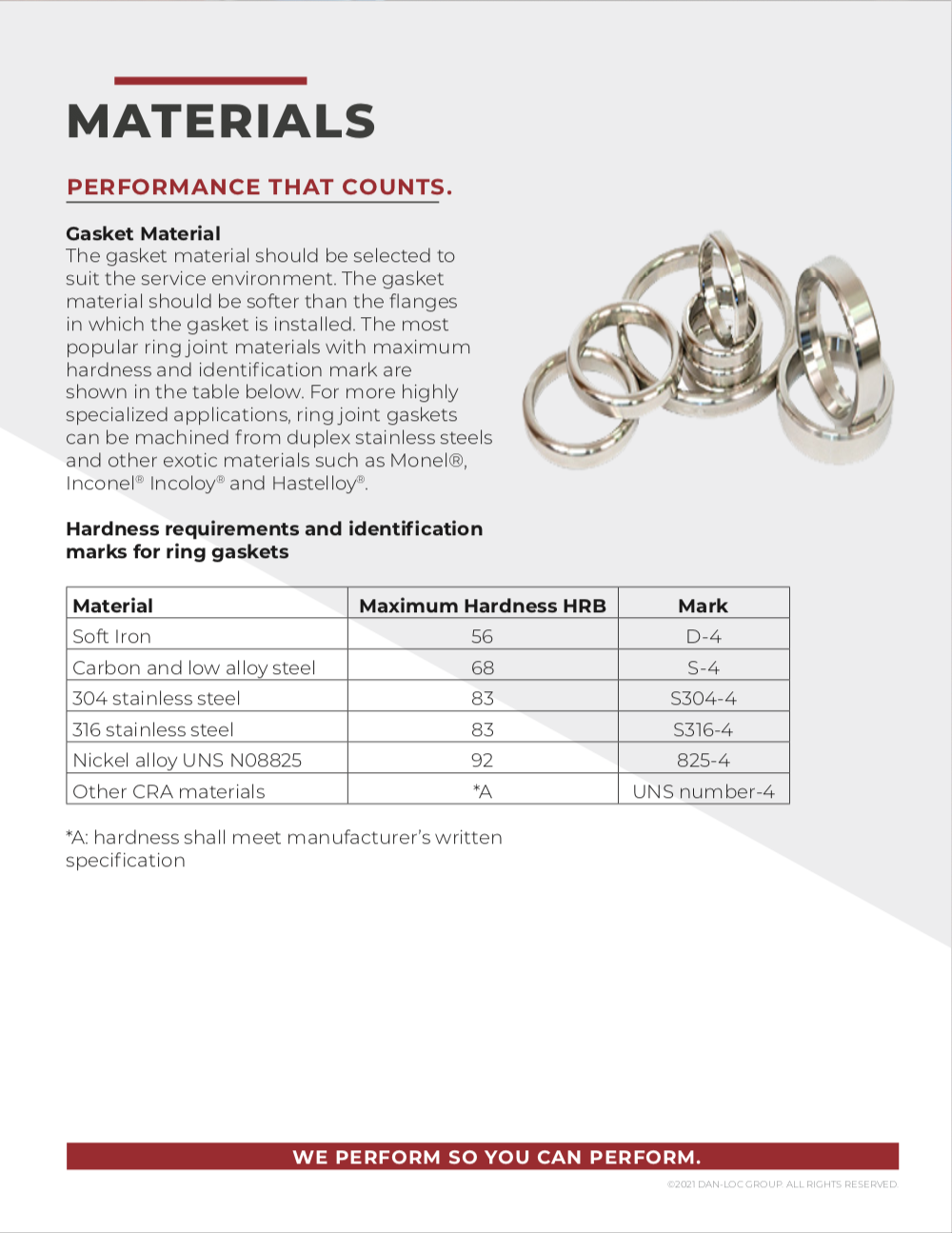

Dedication and commitment to innovative technology and quality control ensures that Dan-Loc Group is the industry leader in machined seal technology. Quality is the emphasis from standard ring joint gaskets to specialized seals.

Dan-Loc Group products follow strict quality assurance procedures and are applied throughout production – from receipt of raw material, through manufacture to delivery and with full material traceability. Dan-Loc Group has a quality system that adheres to the stringent requirements of ISO 9001.

All Dan-Loc Group Ring Joint gaskets are manufactured from fully traceable materials and can be supplied to NACE specifications upon request. Each is low stress stamped with style, a license number, material reference and a unique Dan-Loc Group material identification number. Such full and comprehensive traceability, from material source with mill certification to final supply, is an essential ingredient in the company’s strict quality assurance procedures and exceeds those demanded by the customer and quality governing bodies.

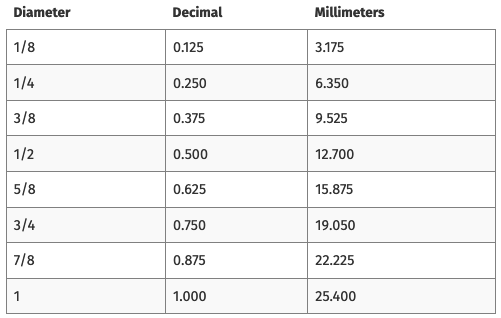

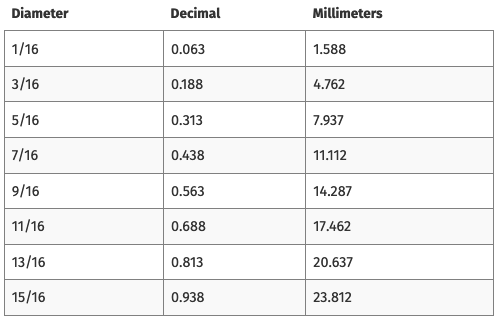

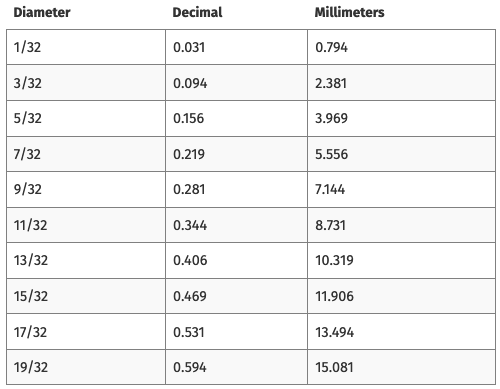

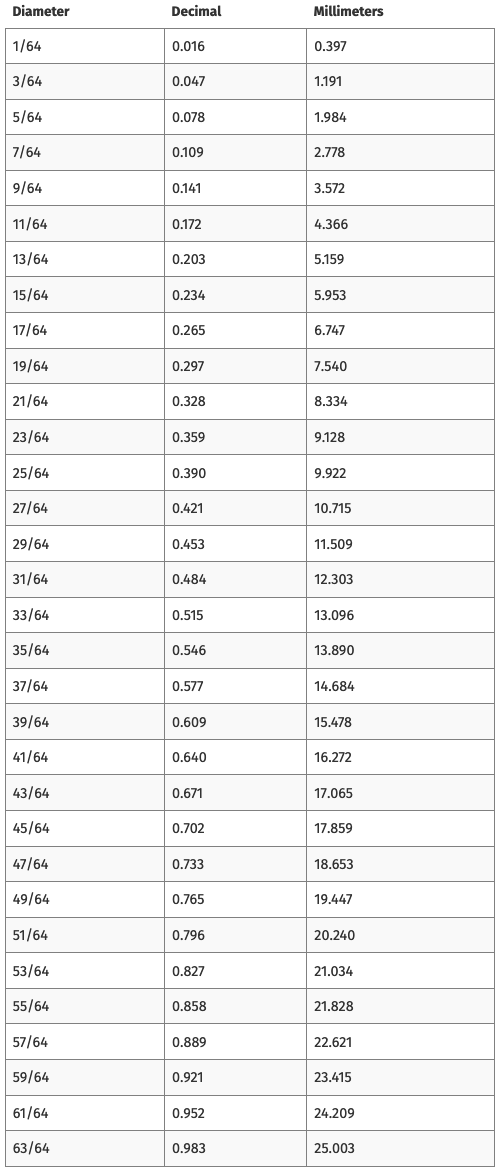

CONVERSION DATA

This information is presented to assist in common dimension conversions from fraction to decimal and millimeters.

EIGHTHS OF AN INCH INCREMENTS

SIXTEENTHS OF AN INCH INCREMENTS

THIRTY-SECONDS OF AN INCH INCREMENTS

SIXTY-FOURTHS OF AN INCH INCREMENTS

Let's Connect!

What can Dan-Loc do for you?

A knowledgeable representative will respond as soon as possible. Thank you!

Dan-Loc Locations

Dan-Loc wants you to have the information you need and answer any questions you have. Please fill out the contact form, email us, or give us a call on the number below.

HEADQUARTERS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - TEXAS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - LOUISIANA

6059 Commerce Pointe Drive, Geismar, LA 70734

Click to call: (225) 644-6449

DAN-LOC EXPRESS - OHIO

294 Fox Drive, Piqua, OH 45356

Click to call: (937) 778-0485

Terms & Conditions of Sale | Legal | Privacy Policy | Employee Portal |

© Copyright 1961-2021 Dan-Loc Group, Inc. All rights reserved. All logos are property of their respective owners.

![]()