GASKETS

& SEALS

RING JOINT GASKETS

Dan-Loc’s ring joint gaskets excel in high-pressure applications such as oil and gas exploration and production. Stocked include Low Carbon Steel, F5, 304 and 316 materials.

- Style R

- Style RX

- Style BX

- Rubber Coated

SPIRAL WOUND GASKETS

Dan-Loc spiral wound gaskets are designed for superior performance and consistent compressibility. These products are durable and easily installed and removed. Ideal for wide range of applications.

- Standard Spiral Wound Gaskets

- With Stainless Steel Inner Ring

- Without Stainless Steel Inner Ring

SPECIALTY GASKETS

Dan-Loc in-house capabilities can machine and manufacture specialty gaskets to your specifications—just supply the prints! Tight tolerances with high finishes.

- Inconel

- Titanium

- Other Exotic Materials

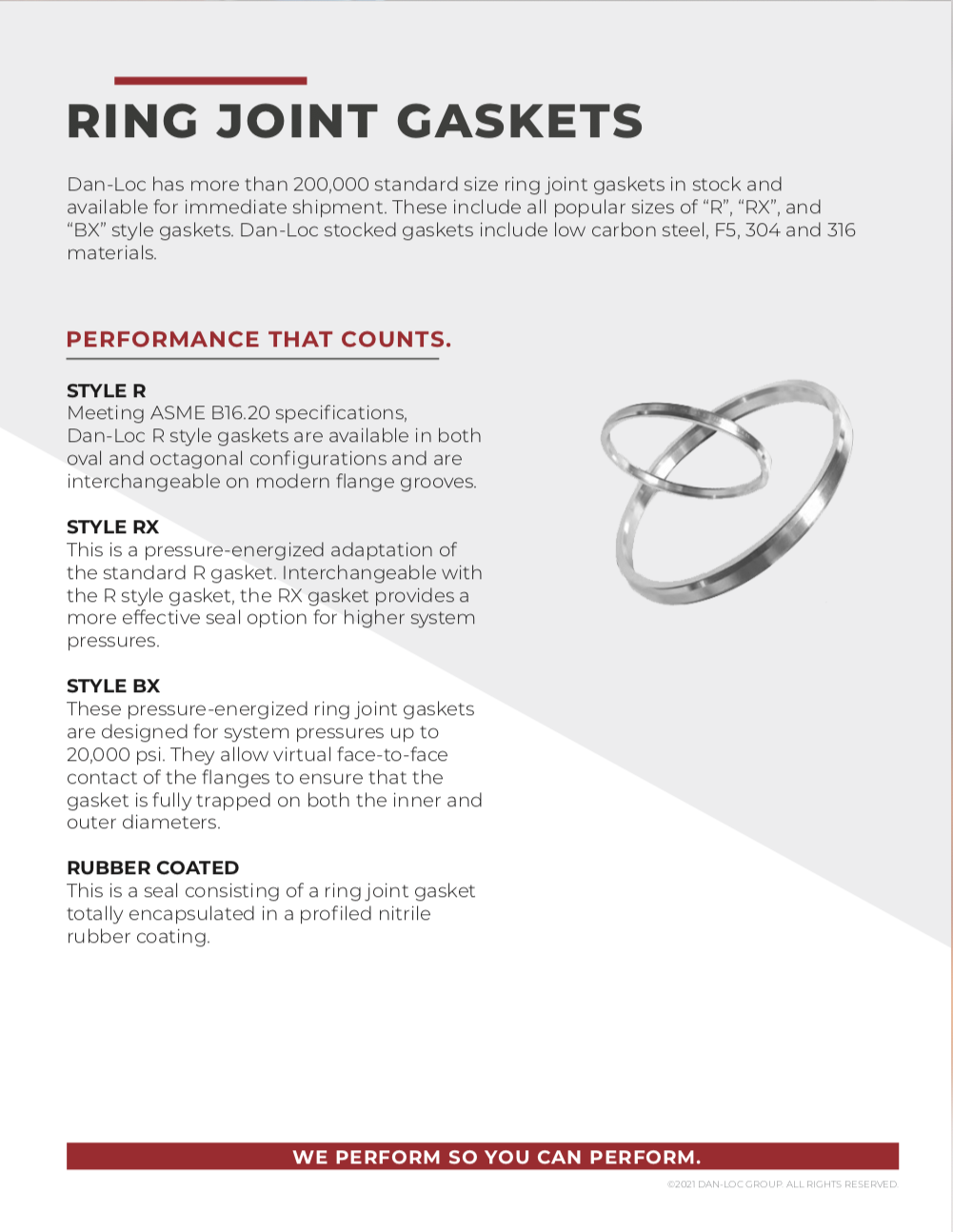

RING JOINT GASKETS

Dan-Loc has more than 200,000 standard size ring joint gaskets in stock and available for immediate shipment.

These include all popular sizes of “R”, “RX”, and “BX” style gaskets. Dan-Loc Group stocked gaskets include Low Carbon Steel, F5, 304, and 316 materials.

Dan-Loc is your single source for all your ring joint gasket needs.

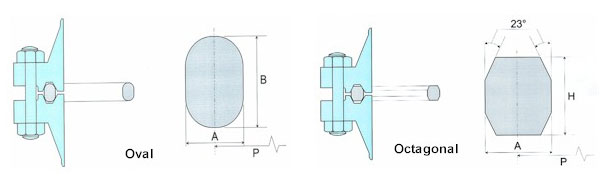

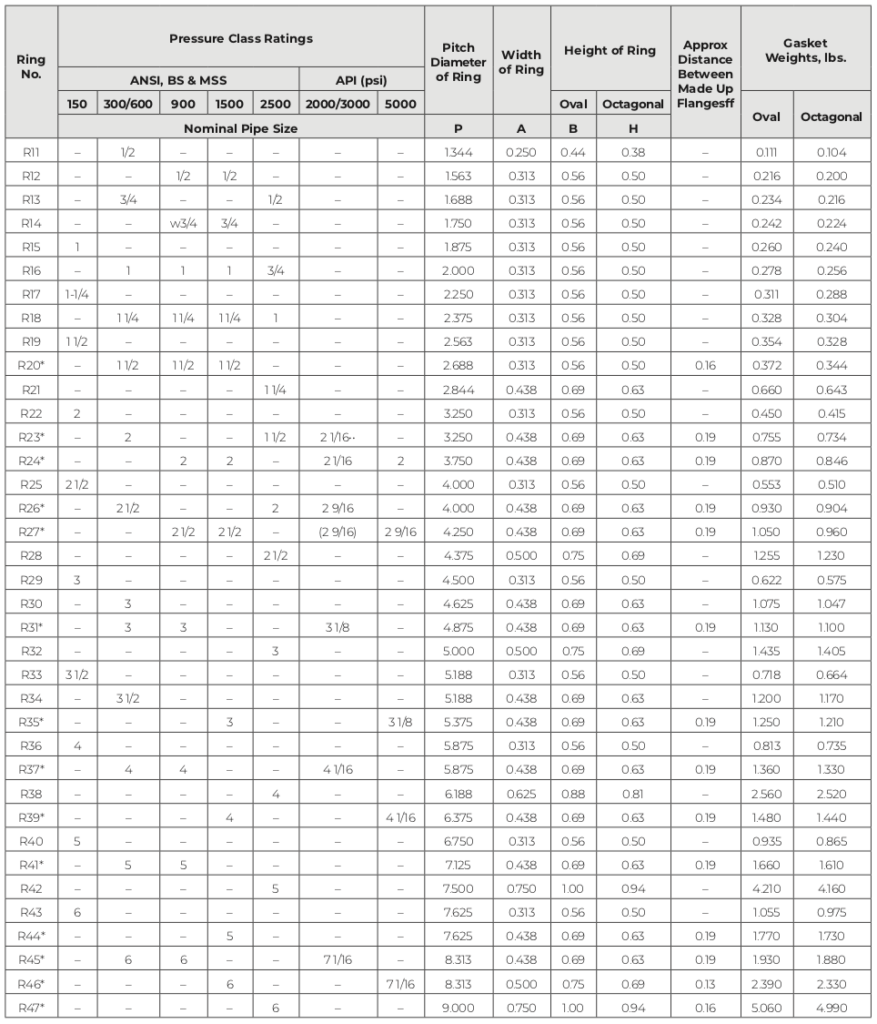

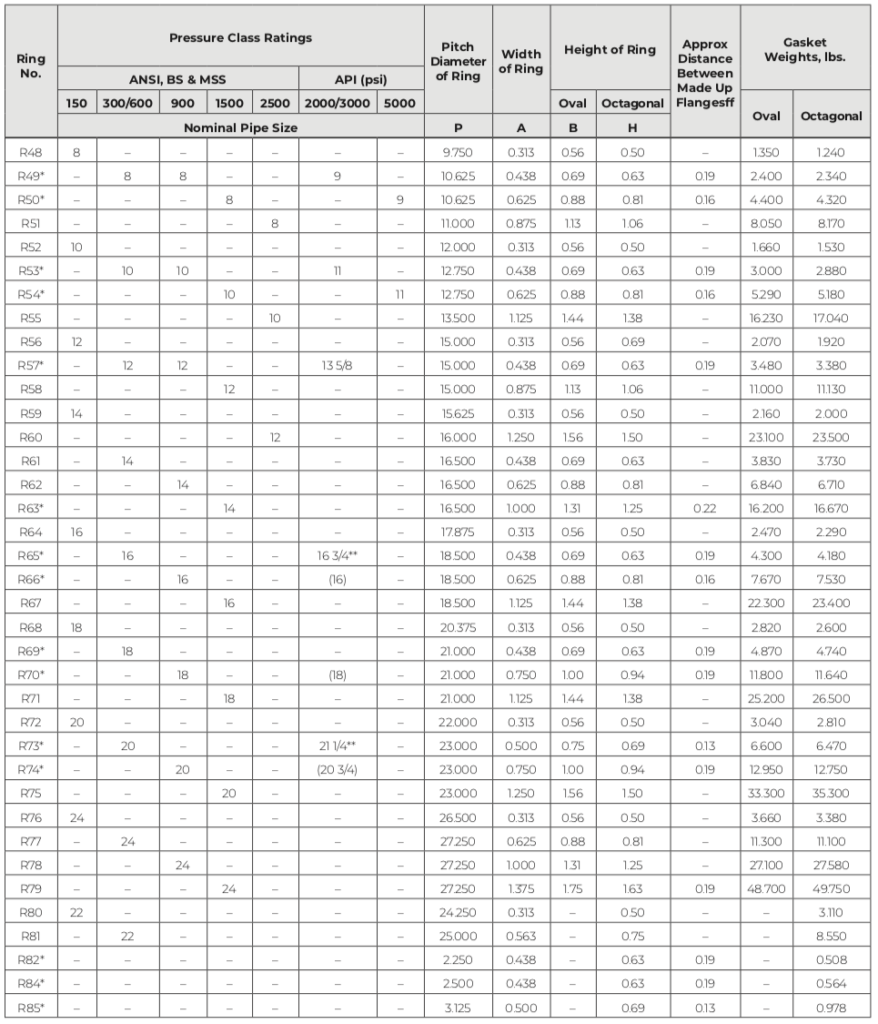

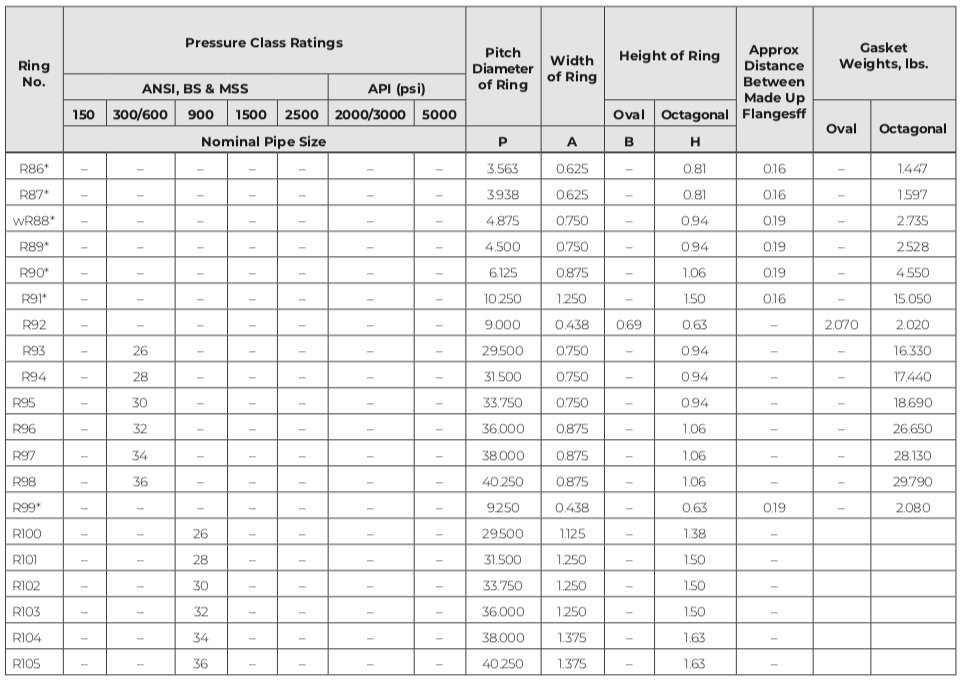

Meeting ASME B16.20 specifications, Dan-Loc Style R gaskets are available in both oval and octagonal configurations and are interchangeable on modern flange grooves.

R ring joint gaskets are manufactured to the specifications of both API 6A and ASME B16.20. They are manufactured in both oval and octagonal configurations which are interchangeable on modern flange grooves.

R Ring Joint gaskets can be manufactured in accordance with all relevant standards to suit the following flange designations:

- ASME / ANSI B16.5

- MSS SP44 ( ASME 16.47 SERIES A )

- BS 1560

Tolerances (inches):

| A* Width of Ring | +/- 0.008 |

| B, Height of Ring | +/- 0.020 |

| P (Average Pitch Diameter of Ring ) | +/- 0.007 |

| 23° (Angle) | +/- 1/2° |

Note: When Ordering, please specify Ring No. ( or Nominal Size / Pressure Class ) and Material.

( * ) Denotes ring number specified in API 6A.

Nominal Pipe Sizes marked ( ** ) apply to class rating 2000 only.

Nominal Pipe Sizes in brackets apply to class rating 3000 only.

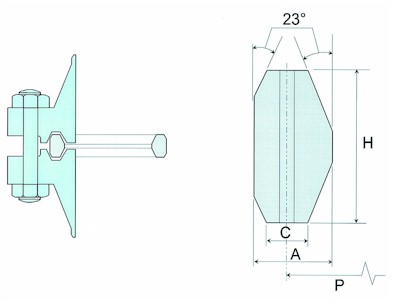

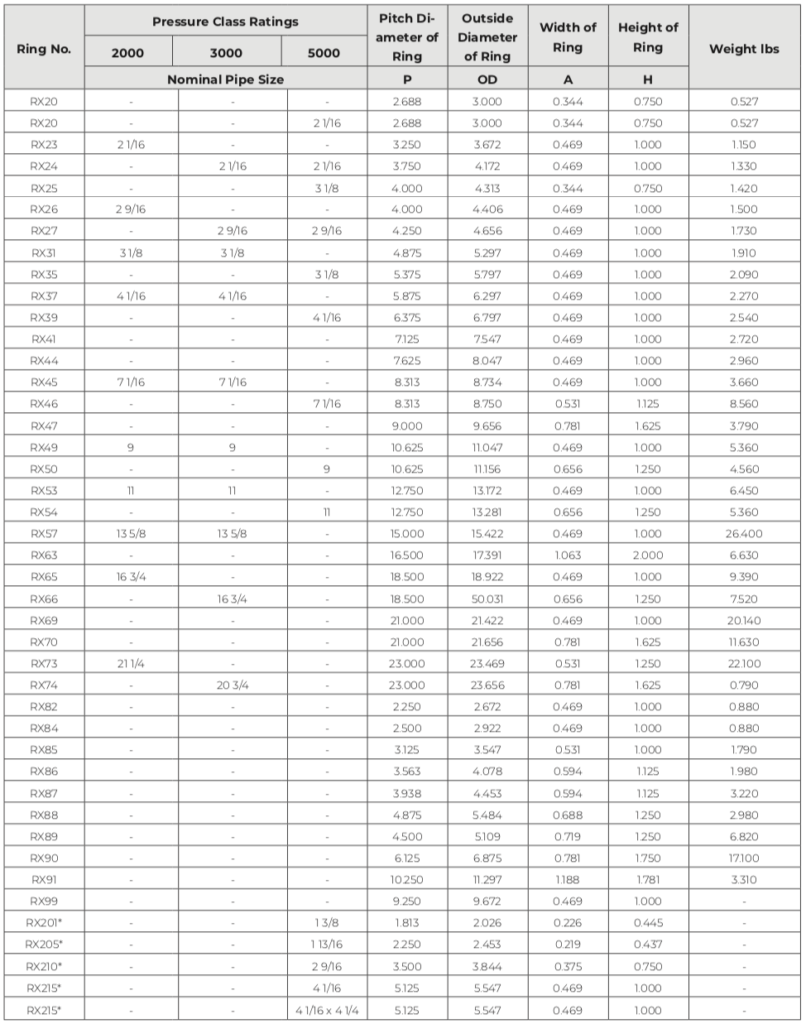

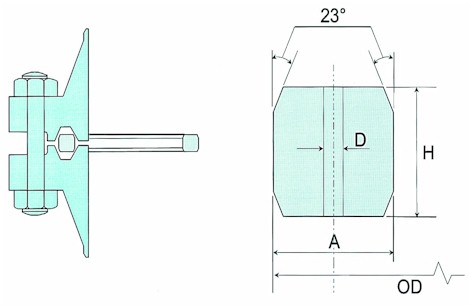

RX ring joint gaskets are a pressure-energized modification of the standard style R ring joint gasket. RX gaskets are designed to fit the same flange grooves as a standard style R

Tolerances (inches):

| A* Width of Ring | +/- 0.008,-0.000 |

| H* Height of Ring | +/- 0.008,-0.000 |

| OD Outside Diameter of Ring | +/- 0.020,-0.000 |

| 23° (Angle) | +/- 1/2° |

* A plus tolerance of 0.008 inches for width ‘A’ and height ‘H’ is permitted provided the variation in width or height does not exceed 0.004 inches throughout its entire circumference.

Note: The pressure passage hole illustrated in the RX Ring Cross section is in Rings RX82 through RX91 only. Center line of hole shall be located at mid point of dimension ‘C’ ( width of flat).

* API allows more liberal tolerances on RX 201–215

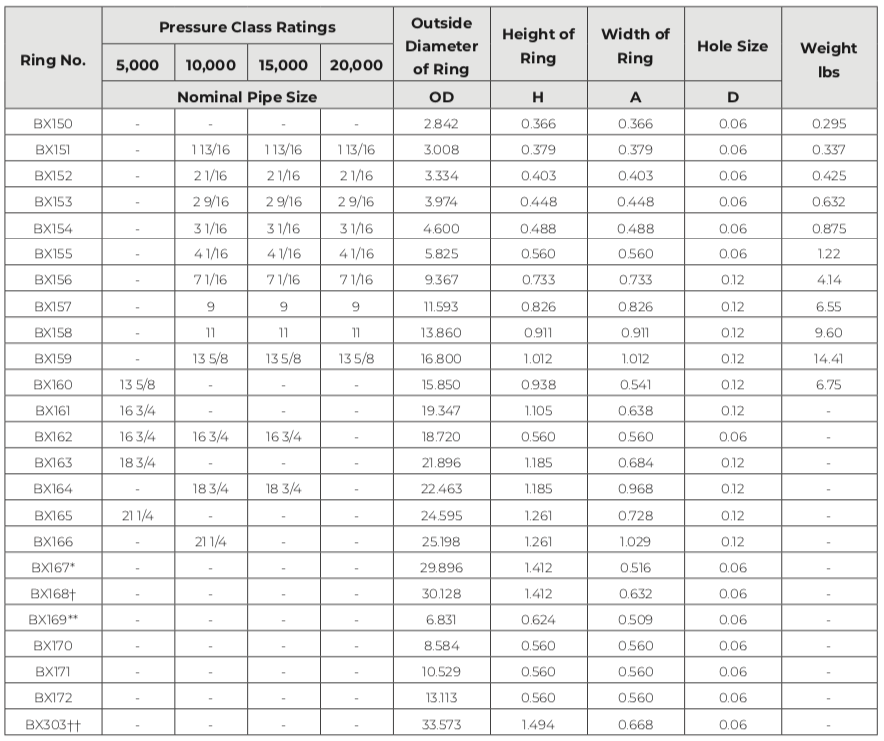

BX ring joint gaskets are manufactured to the specifications of API 6A. They are pressure-energized gaskets designed for use on systems up to 20,000 psi.

BX gaskets are designed to allow virtual face-to-face contact of the flanges to ensure that the gasket is fully trapped on both the inner and outer diameters.

BX gaskets include a pressure balance hole to allow equalization of pressure which may build up in the grooves.

Tolerances (inches):

| A* Width of Ring | +/- 0.008,-0.000 |

| D Hole Size | +/- 0.02 |

| H* Height of Ring | +/- 0.080,-0.000 |

| OD (Outside Diameter of Ring ) | +/- 0.000,-0.006 |

| 23° (Angle) | +/- 1/4° |

Note: One pressure passage hole required per ring on center line.

*A plus tolerance of 0.008 inches for width ‘A’ and height ‘H’ is permitted, provided the variation in width or height does not exceed 0.004 inches throughout its entire circumference.

*BX167 is suitable for 26¾ Nominal Pipe Size 2,000 psi rating.

**BX169 is suitable for 5¾ Nominal Pipe Size 10,000 psi rating.

BX168 is suitable for 26¾ Nominal Pipe Size 3,000 psi rating.

BX303 is suitable for 30 Nominal Pipe Size 2,000 and 3,000 psi rating.

This is a seal consisting of a ring joint gasket totally encapsulated in a profiled nitrile rubber coating.

The rubber coating provides added sealing and protects the flange surfaces as well as providing corrosion protection. Rubber coated gaskets are used for pressure testing to minimize damage to the flanges.

GASKET DATA SHEETS

SPIRAL WOUND GASKETS

Spiral wound gaskets are designed to maintain a seal in flanged joints under severe fluctuations of temperature and pressure. Dan-Loc stocks standard spiral wound gaskets with and without stainless steel inner rings.

We provide fast service on special sizes and materials of spiral wound gaskets. Let’s explore how we can meet your needs.

SPECIALTY GASKETS

Dan-Loc has machining capabilities to manufacture special gaskets made to customer prints in all materials including inconel, titanium, and other exotics. We have the capability to manufacture gaskets to tight tolerances and high finishes.

Custom Manufactured Seals

Dan-Loc manufactures a full range of machined sealing components with or without coating and with or without additional elastomeric seals.

GASKET MATERIALS

The gasket material should be selected to suit the service environment. The gasket material should be softer than the flanges in which the gasket is installed.

The most popular ring joint materials with maximum hardness and identification mark are shown in the table to the right or below.

For more highly specialized applications, ring joint gaskets can be machined from duplex stainless steels and other exotic materials such as Monel®, Inconel® Incoloy®, and Hastelloy®.

Hardness requirements and identification marks for ring gaskets:

| Material | Maximum Hardness HRB | Mark |

|---|---|---|

| Soft Iron | 56 | D-4 |

| Carbon and low alloy steel | 68 | S-4 |

| 304 stainless steel | 83 | S304-4 |

| 316 stainless steel | 83 | S316-4 |

| Nickel alloy UNS N08825 | 92 | 825-4 |

| Other CRA materials | *A | UNS number-4 |

Why You Want Dan-Loc On Your Team

Dan-Loc is your trusted stud, rod, bolt, nut, fastener and gasket supply partner. We stock for your day-to-day needs, and are able to scale to projects of any size or manufacturing equipment customer need.

Let's Connect!

What can Dan-Loc do for you?

A knowledgeable representative will respond as soon as possible. Thank you!

Dan-Loc Locations

Dan-Loc wants you to have the information you need and answer any questions you have. Please fill out the contact form, email us, or give us a call on the number below.

HEADQUARTERS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - TEXAS

725 North Drennan Street, Houston, TX 77003

Click to call: (800) 231-6355

Click to call: (713) 356-3500

DAN-LOC EXPRESS - LOUISIANA

6059 Commerce Pointe Drive, Geismar, LA 70734

Click to call: (255) 644-6449

DAN-LOC EXPRESS - OHIO

294 Fox Drive, Piqua, OH 45356

Click to call: (937) 778-0485

Terms & Conditions of Sale | Legal | Privacy Policy | Employee Portal |

© Copyright 1961-2021 Dan-Loc Group, Inc. All rights reserved. All logos are property of their respective owners.

![]()